sierraclub.org - sierra magazine - march/april 2013 - corporate climbers

Trading granite walls for giant turbines, mountaineers cash in on their rope skills to keep America's wind farms humming

Text and photography by Andy Isaacson

If you've driven across California, you've probably seen wind turbines along the freeway. You might have found them a curious sight, or perhaps a reason for optimism about the future of the planet. Maybe they reminded you of a nesting flock of cranes—some pecking madly, others dead still.

Josh Crayton looks at them as if they were luxury cars. "These are Mitsubishi 1.0s—one-megawatt turbines—the cleanest Mitsubishi turbine you will ever see," he said, pointing them out to me on a recent drive. "But the Cadillacs are these Siemens. They're sexy as all hell."

We were on a two-lane county road about 50 miles east of San Francisco, in the rolling grassland of Altamont Pass, which once produced half of the world's wind-generated electricity.

Crayton, 38, who has close-cropped reddish-brown hair and a laid-back manner, works as the blade-service manager for Rope Partner, a Santa Cruz-based outfit that cleans and maintains wind turbines across North America. I was driving with him and Ryan Gaunt, one of the company's project managers, to inspect a turbine blade on a 6,100-acre wind farm in the Sacramento Delta.

"Many of our employees have climbing in their makeup,"

Crayton said. "They work six weeks on wind turbines, then go out on their next big excursion."

Both men are serious climbers. Crayton has blazed new climbing routes around Sedona, Arizona, and Gaunt used to spend several months a year living out of his car at various climbing spots around the West. Their morning commute had the feel of a sport-climbing excursion. We'd all met before dawn in the parking lot of a Berkeley climbing gym; the backseat of their four-door pickup was cluttered with helmets, thermoses, salami, crackers, and Luna bars.

Crayton fell into this niche of the wind power industry about eight years ago. At the time, he was in college, planning to become a teacher. After spending a summer guiding rafting trips in the Sierra Nevada, he was driving home to Flagstaff, Arizona, when his car broke down in the mountains. He didn't have the money to fix it, but he'd heard that Rope Partner was hiring rock climbers to clean and repair turbines. So he signed up for the company's weeklong training course in Santa Cruz and two weeks later found himself dangling from a wind turbine. "I was thinking to myself, 'My God, really?'" he recalled of the moment when he realized he could make a living doing something he loved. "It was what I'd been waiting for my whole life."

Rope Partner's field technicians can live anywhere they want, as long as it's reasonably close to an airport. Many base themselves near outdoor havens so they can play in their spare time. "If technicians had to live in Iowa or Texas, nobody would do it," Crayton said. "They wouldn't have anywhere to climb." The company flies them to repair sites, where they might spend up to five months on location and then afterward take a long vacation. The irregularity of this schedule, and its seasonality, is precisely the appeal.

"Many of our employees have climbing in their makeup—it's part of who they are," Crayton said. "Instead of earning a minimal amount as a river guide or a climbing guide, they work six weeks on wind turbines, come home with a chunk of money padding their pockets, and then go out on their next big excursion. They can go to Patagonia and spend three months hanging out in a tent, waiting for it to stop raining."

* * *

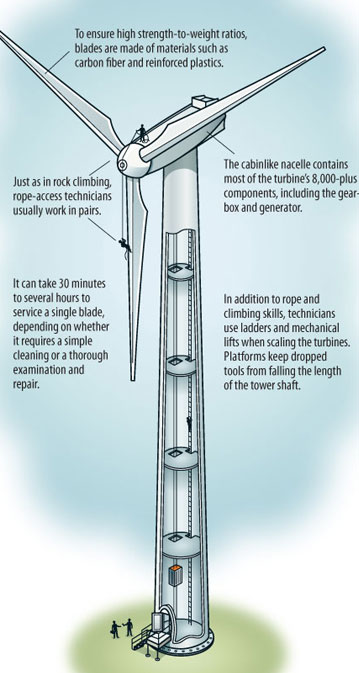

Peter and Maria Hoey

Peter and Maria Hoey

An hour's drive southwest of Sacramento, the sprawling, 150-megawatt Shiloh II Wind Project features 75 gleaming white turbines on rolling ranchland in the Montezuma Hills. Shiloh II is owned and operated by EDF Renewable Energy, an independent producer out of San Diego that sells the power generated by the site to Pacific Gas & Electric Company.

On the bright, balmy morning we arrived, most of the turbines stood motionless because of light wind—ideal conditions for working 25 stories off the ground. "Still as can be," Crayton said. "It's spectacular, and just going to get better."

We headed to a complex of low-slung buildings in the middle of the wind farm, where EDF had us sign safety paperwork. The company's technician led us through the hills along a narrow road, then up a driveway that ended at the base of a turbine. It was a REpower MM92 two-megawatt turbine, 260 feet tall, with three 150-foot gently curving blades: not a Siemens but still sexy as all hell.

Crayton and Gaunt unloaded their gear and suited up with routine efficiency. Each strapped on a harness, a helmet, and a headlamp and then began clipping on safety latches, straps, nylon bags (no chalk), and a small digital camera. The technician from EDF scaled an internal ladder to the top of the tower and lowered a cable through an opening to hoist up the heavy climbing ropes. Crayton checked the two-way radios, while Gaunt parked the truck 100 feet from the base of the turbine and placed a sign on the windshield that read, danger: hazard zone. persons working overhead.

Companies like Rope Partner exist because rope access is the cheapest way to maintain the surfaces of wind turbines. Not many cranes are tall enough to service modern turbines, and they are expensive to transport. "It's a no-brainer to hire two guys to fly in with a couple of bags," Crayton said.

Although the work appears dangerous, the hazards for seasoned climbers are minimal and mainly environmental: snakes and spiders around the base, wind chill and falling ice in winter, intense heat in summer. Typically, turbine technicians stay grounded if the wind blows more than 25 miles per hour or if lightning strikes within 30 miles, so it's rare that they find themselves in dangerous weather conditions. Falling gear can be a concern, and although the climbers adhere to strict safety protocols, there's also the obvious risks anytime they're on the ropes.

Crayton and Gaunt directed the EDF technician to rotate the blade into a vertical ("bunny ear") position and then lock it in place to prevent it from spinning. They climbed the ladder to the top, where they clipped a pair of neon yellow ropes to the metal frame that held the turbine's gearbox and generator. They tossed over their ropes, stepped backward through an opening, and rappelled onto the lower blade.

For the next hour, Crayton made his way down one side, Gaunt down the other. They surveyed the surface for wear and tear, taking snapshots. Fiberglass erosion, chipped paint, and even insect buildup can prevent the turbines from running optimally. Sometimes Rope Partner is hired to simply clean the blades' surfaces, a task that can take several weeks on a farm containing dozens of turbines. Crayton said that some owners are more concerned with keeping the costly gearboxes in order and often put off blade maintenance longer than they should.

Workers seldom use power washers to clean the outside surfaces of a turbine, because doing so can spatter hydraulic and gearbox oil onto the ground. Instead, cleaning teams typically employ old-fashioned techniques.

"It's spit and shine, man," Crayton said. "It's rags. It's Simple Green."

1 | 2 | next >>